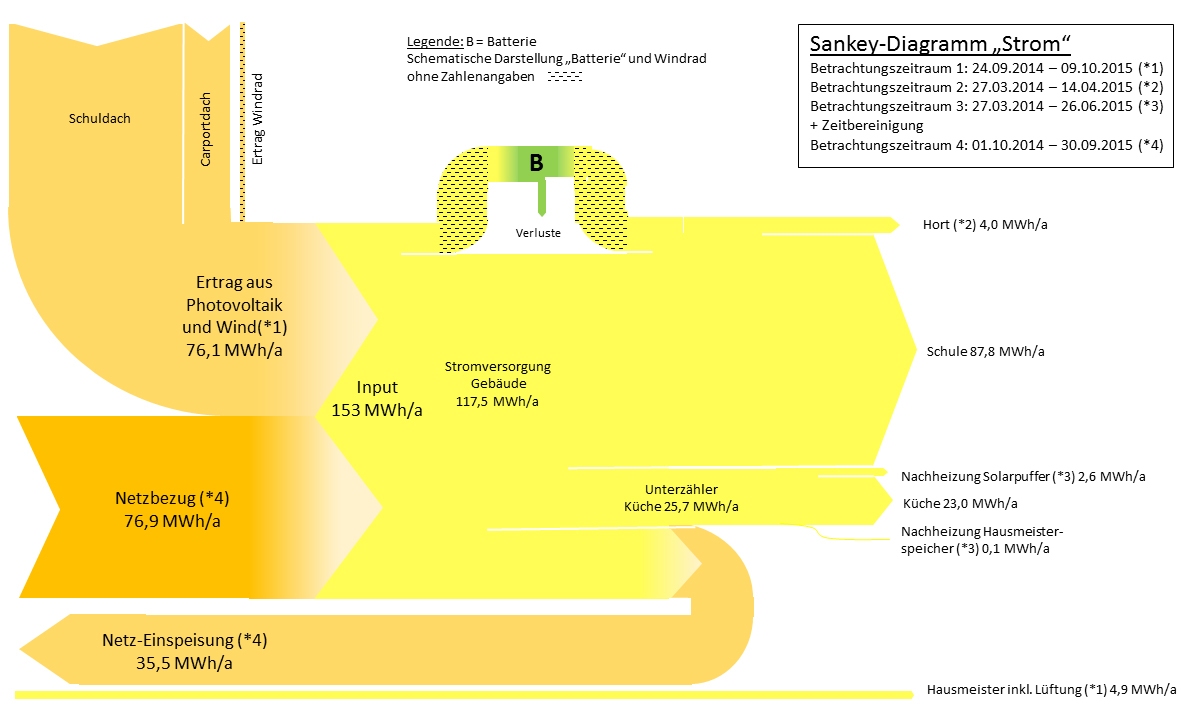

This Sankey diagram on wood biomass flows in the Netherlands is featured in the study ‘Sustainable biomass and bioenergy in the Netherlands’ by Goh, Mai-Moulin and Junginger from Utrecht University.

Flows are in million tons (MT) dry mass for the year 2014. The diagram has a very clear structure. Import streams are from the top and exports leave to the bottom. Domestic Dutch production is from the left, use of wood biomass in the Netherlands is to the right. Paper and cardboard, alongside pulp are the largest flows, but mainly being imported and exported again, or circulating domestically as recycled paper.

The report has two other Sankey diagrams on oils and fats and carbohydrates used in different sectors in the Netherlands. See the full report here.