Those of you who have already created Sankey diagrams might have come across the issue: As long as the flow data you are about to visualize is more or less in the same value range everything is fine, and there should be no problem in coming up with an nice Sankey diagram. However, sometimes we have very small flow quantities, while at the same time there are some large flows dominating the picture.

Sticking to the “golden rule” of Sankey diagrams (i.e. the width of the Sankey arrow corresponds to the flow quantity represented) and ensuring the proportionality of flows in relation to each other becomes very difficult. If you opt to show the larger flows at “normal” width, the smaller flows become difficult to perceive and are shown as hairlines (sometimes even invisible on a screen or in print). If, on the other hand, you decide to push up the scaling factor so that these smaller flow quantities can be seen in the diagram, then the large flows are really fat and spoil your diagram.

This seems to be an irresolvable issue… Nevertheless, there are some approaches to tackle this. Most of them resort to taking out the tiny flows or the very large flows of being to scale used in the Sankey diagram. You may opt to use a minimum width (e.g. 1 or 2 pixels) for arrows that carry only a small flow quantity, or you may decide to set an upper flow threshold, corresponding to a maximum width for the Sankey arrow, independent of the actual flow quantity (beyond the threshold value). In both cases I would strongly recommend to denote this decision in the diagram (e.g. in a footnote), since otherwise the person looking at the Sankey diagram will get a wrong idea of the quantities/proportions.

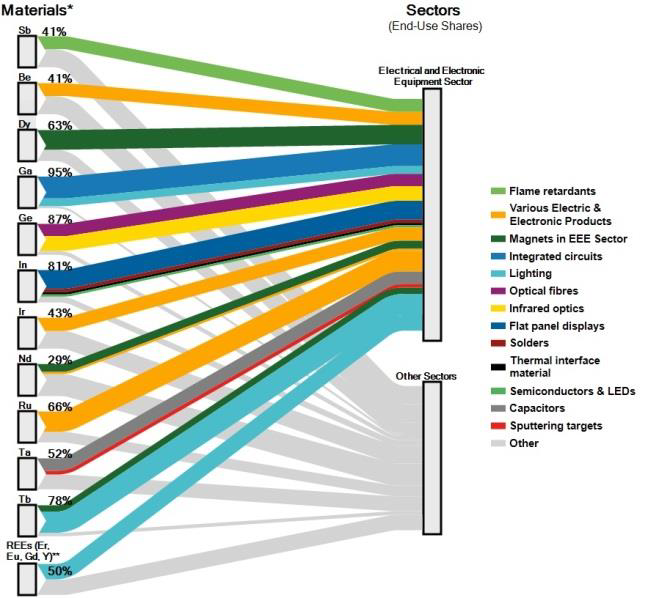

The Sankey diagram from the PROSUM report I recently featured in this post has another, quite unique solution. Here is a zoomed cropped section:

The metals in the end-of-life vehicle (ELV) stream of 8 million tons (in 2016) are mainly aluminium, copper and iron. This stream is on the same scale as the overall Sankey diagram (see full diagram here). However, the other metals in the stream (such as gold, silver or platinum) are contained in comparatively much smaller amounts. The authors of the Sankey diagram hence opted to emphasize them by switching to another scale (1:5.000). As a result the arrow representing the flow of approximately 660 tons of critical raw materials (CRMs) is almost a wide as the arrow that shows 6780 ktons!

The fact that the precious metal stream is highlighted and not to scale with the rest of the flows in the diagram is clearly signalled with a note, a dotted line that separates this diagram area, and even an exclamation mark symbol.

Since CRMs were the focus of the PROSUM study I think such a “trick” is justified. What are your experiences with flows on different scales? How would you handle this “dimension challenge” in a Sankey diagram? Let me know your ideas!