The Mexican National Commission on Energy Saving (Comisión Nacional para el Ahorro de Energía (CONAE) present several success stories (casos exitosos) on their website.

One success story dates back to 1997, and describes how an energy efficiency study of fired heaters (i.e. boilers) was carried out in a Nafta producing facility in the Veracruz state of Mexico. As a result of the study, several suggestions for optimization were implemented. Fuel consumption could be reduced by 23-24 %, while the efficiency of the ovens could be raised by 13% (calentador BA-2001 B) and 16% respectively (calentador BA-2001 A).

Para los hispanoparlantes: el título oficial del proyecto fue “estudio técnico económico e ingeniería conceptual realizada a los calentadores a fuego directo BA-2001 A/B de la planta hidrodesulfuradora de naftas, del C.P.Q. “La Cangrejera”, ubicado en Coatzacoalcos, Veracruz” (otro candidato para el concurso mundial de titulos largos).

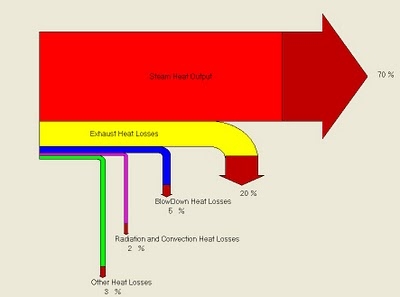

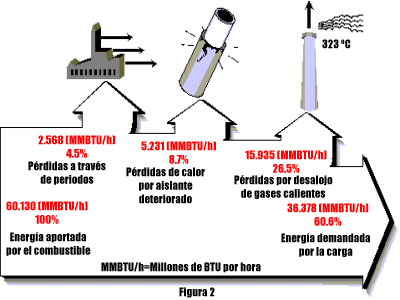

The heat losses are shown as Sankey diagrams. The first describes the optimal situation, with an energy efficiency of 82,4 % “as guaranteed” by the maker of the fired heater.

The two other Sankey diagrams show the energy balance of the heaters A and B before the implementation of the measures. They run with an efficiency of 60,6 % and 62,35 %, a “real world situation of one fired heater” /

The arrows branching off at the top show the heat losses. I like the fancy icons that show how energy is lost through the walls, because of deteriorated or insufficient insulation, and heat energy in the effluent gases. The flows are given in MMBTU/h (millions of BTU per hour).

Unfortunately two of the diagrams are not to scale: The arrow to the right in the second diagram should be roughly 2/3 of the width on the left side. It is about 4/5 (or 80 %) of the width, similar to the width in the first Sankey diagram. This is a visual exaggeration of the inefficiency. However, I refrained from featuring this in my informal “Lying with Sankey diagrams” series. 😉

Edit 05/2015: the web pages are not acessible any more. I had to restore the image from a local copy, and removed references to two other diagrams I had references to. -Phineas…