Almaty is the largest city in Kazakhstan. It is also the first city in Central Asia that did a circular economy opportunities analysis. Numerous ideas were proposed during a project with local stakeholders.

The project is described on the Shifting Paradigms blog, and the full report ‘Metabolic analysis and circular economy strategies for Almaty, Kazakhstan’ describing the project can be downloaded there.

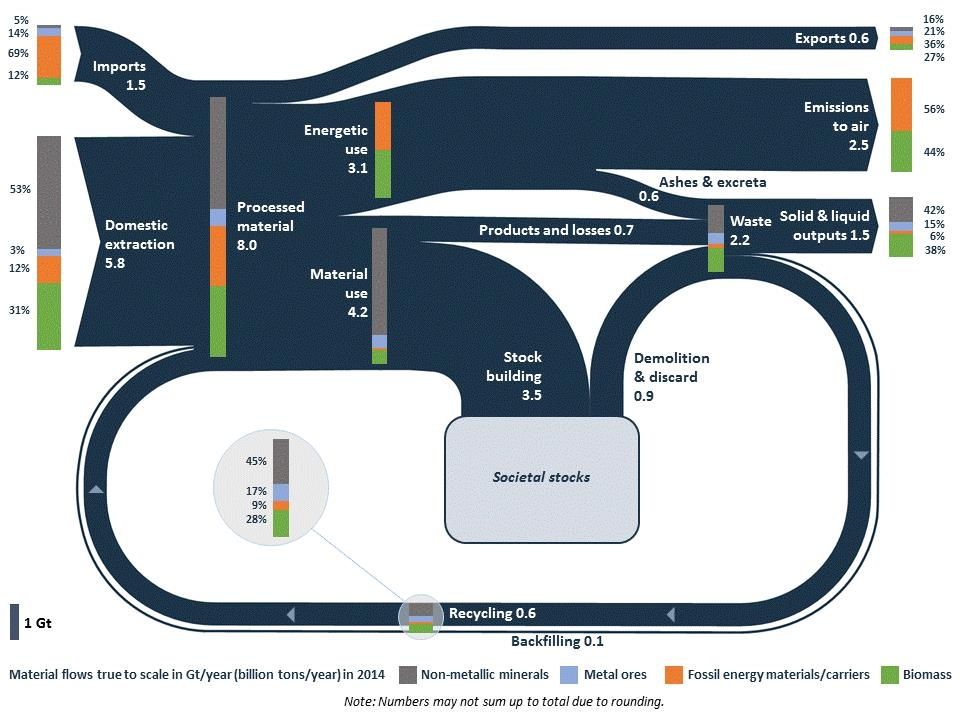

Visuals turned out to be crucial in this project for communicating information and to be able to oversee the amount of data. “Mapping out the metabolic system of a city, helps understand how a city uses material resources to deliver valuable services to its inhabitants, like nutrition, shelter and mobility, and identify opportunities for improvement.”

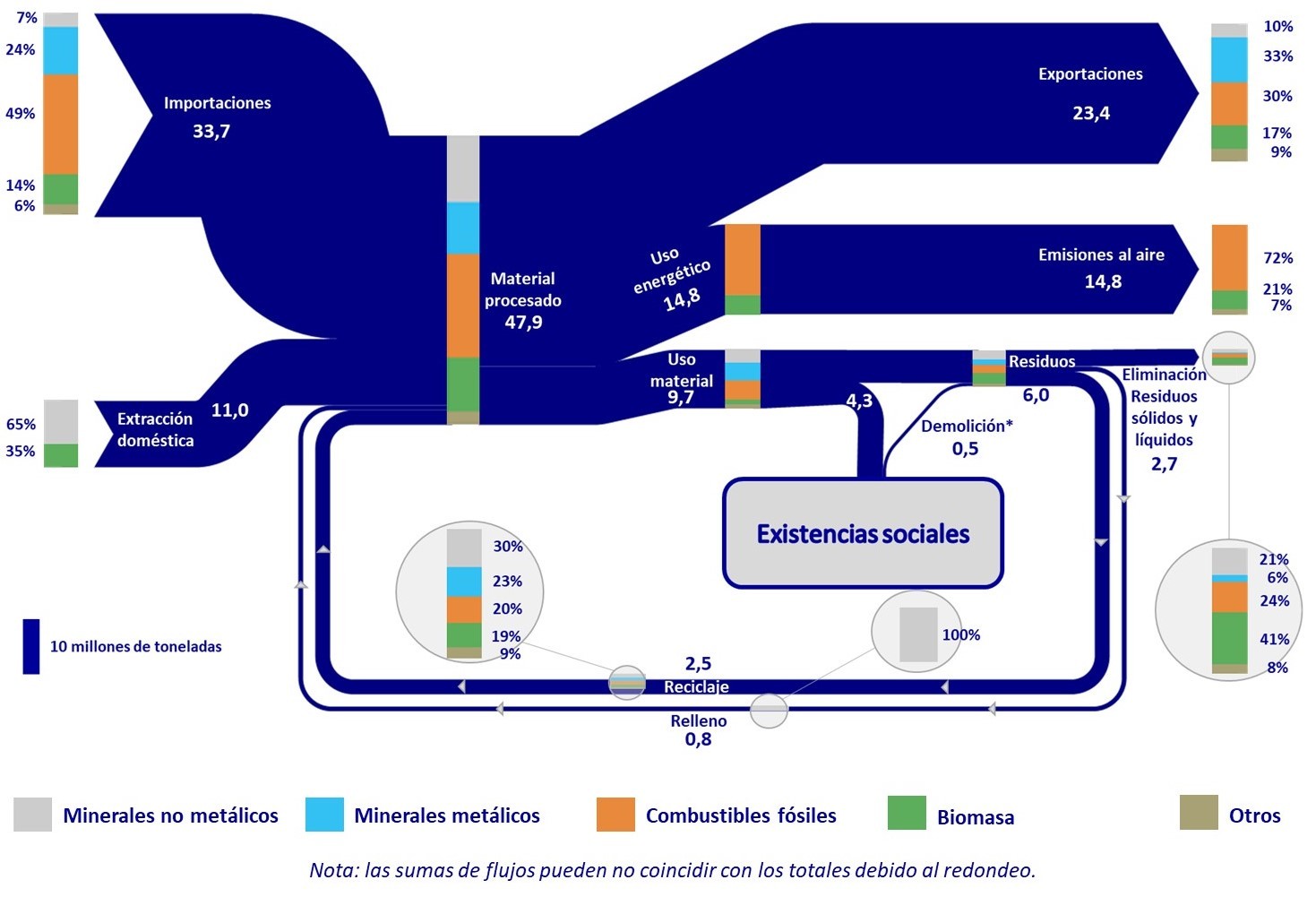

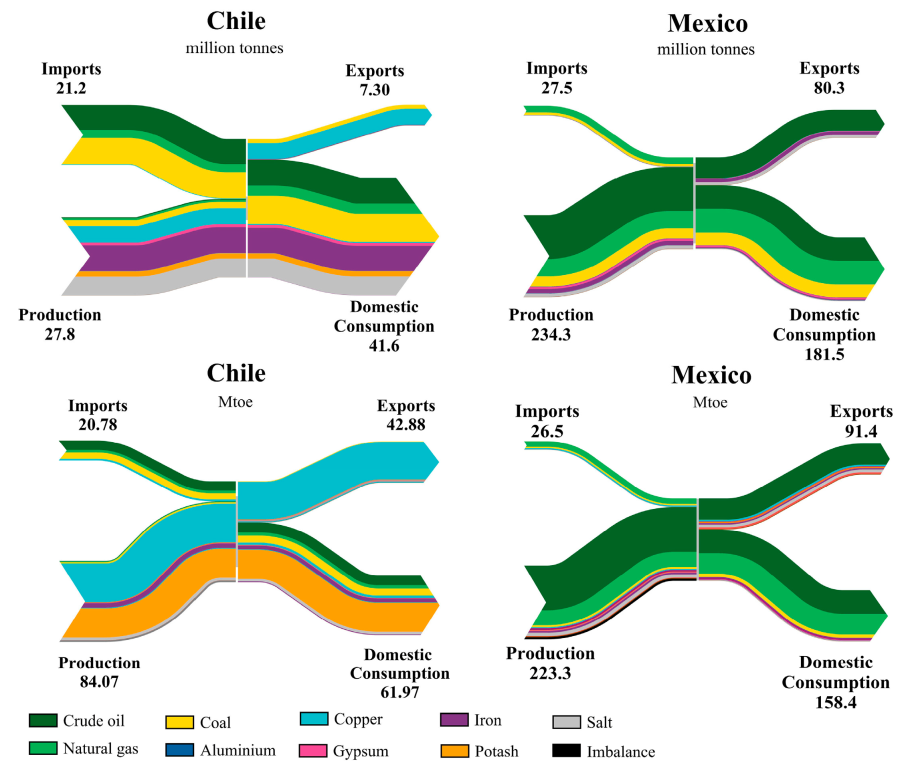

This is the Sankey diagram depicting the material flows for Almaty, Kazakhstan covering minerals, metals, biomass, fossil fuels, energy and water used in Almaty’s industry. It is shown on pages 36/37 of the report. Flows are in kT (per one year ?) with imports/exports across the city’s boundaries.

Blended into this material flow analysis (MFA) diagram are greenhouse gas emissions (GHGs). “The red flows at the lower section of the graph show the embedded gas emissions in imported goods and materials.” These could be considered hidden quantities associated with the production of products or the import of fuels, “piggybacking” on the actual physical material flows that enter and leave the industrial sector in the city.

Note that it seems as if flows are not always to scale or parts are hidden behind other flows (see, for example, the yellow stream representing 968 kT of fuel being turned into 2,975 kT GHGs, a flow that is not three times as wide). Also the recycling flow width seems to overblown, probably to point out that recycled materials can loop back through the system multiple times, and to focus the circular economy perspective.

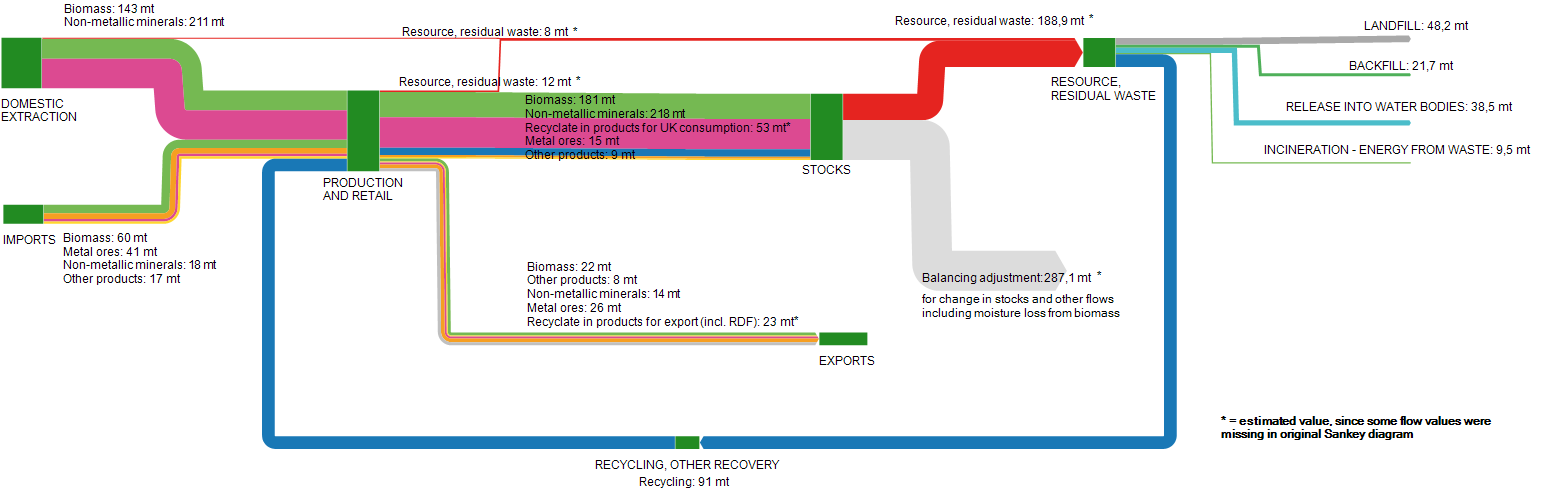

There are two other Sankey diagrams in the report, so make sure you have a look at it.