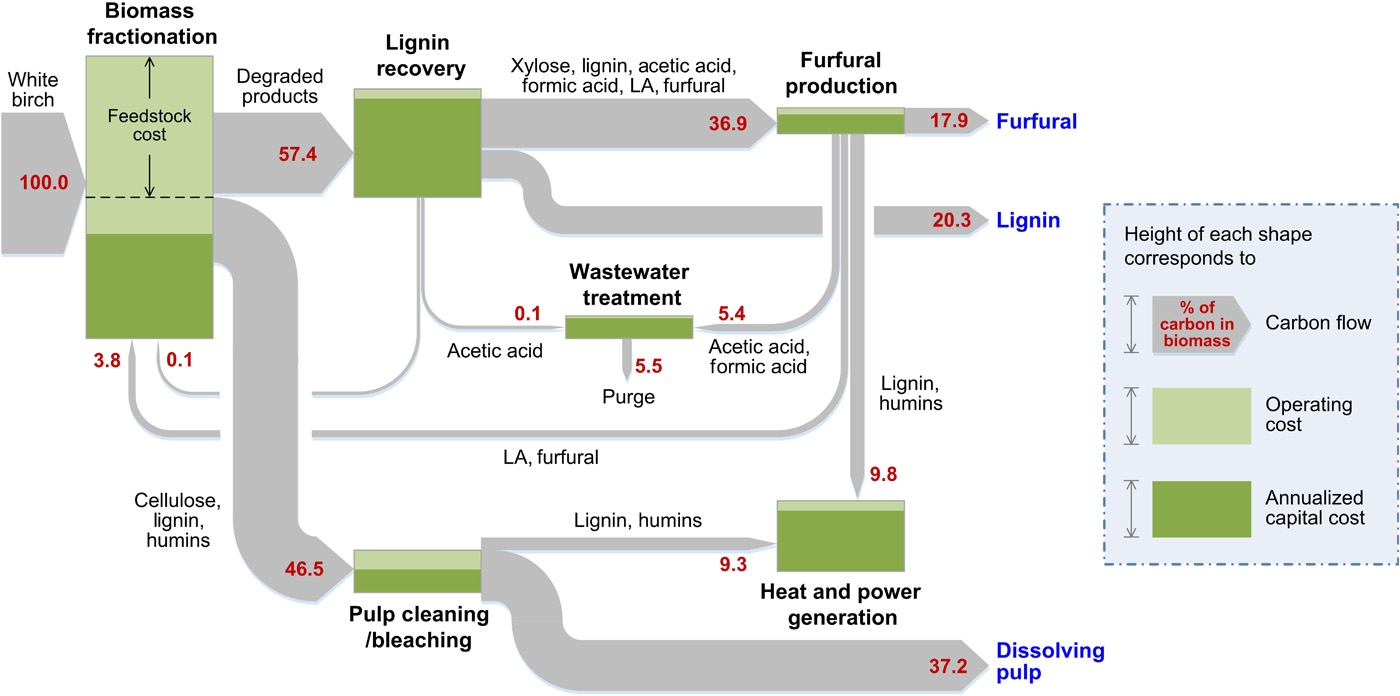

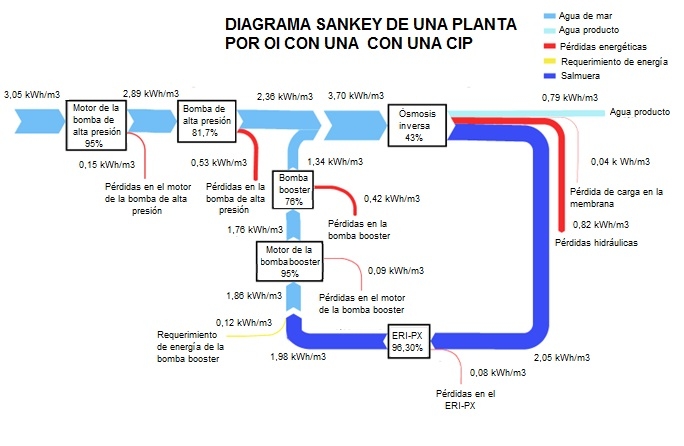

A comment from a reader pointed me to this Sankey diagram for energy flows in an air compressor system. It can be found as a sample on the web page of VHK Research Engineers. VHK uses Sankey diagrams to “get the message across”.

(Image copyright: European Union, author: VHK)

This is a rare example of a top-down oriented Sankey diagram. There are no absolute numbers, rather we see the 100% energy being turned into useful work, and off-heat, which could potentially be recovered.

Nice piece of art, and I invite Rene to comment on this…