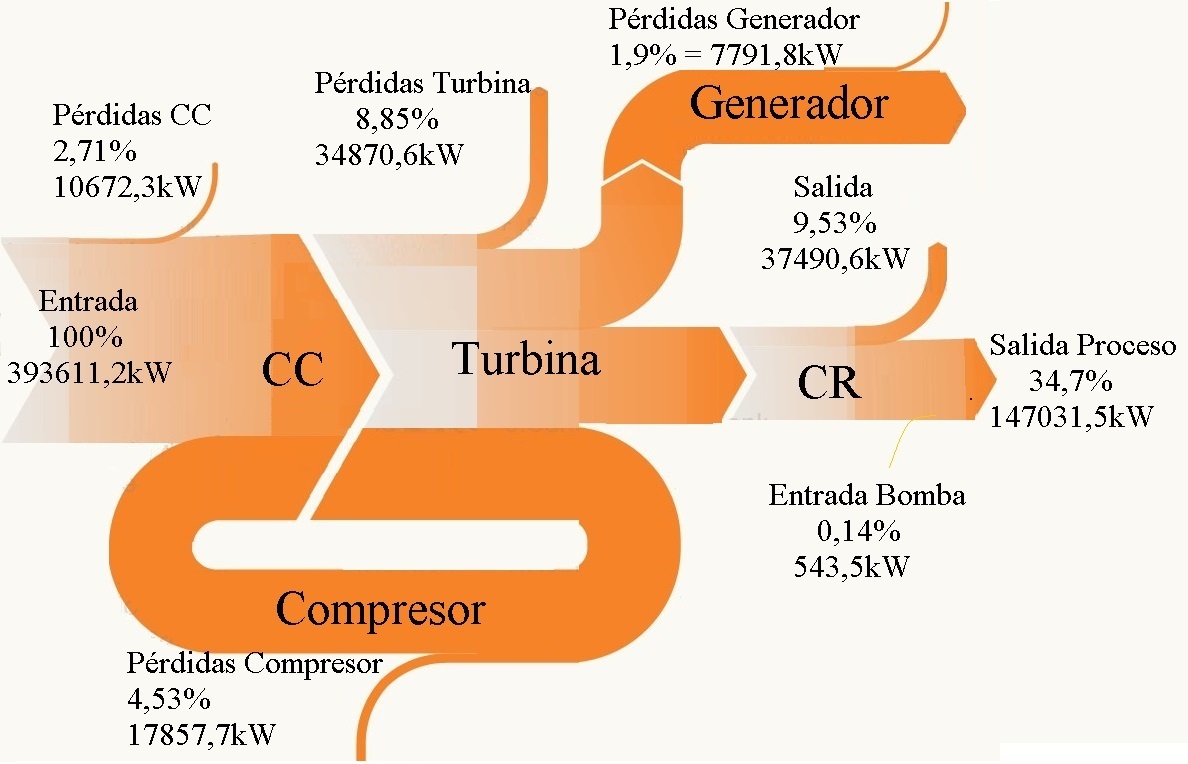

An analysis of energy efficiency and exergy effciency of a cogeneration system in a sugar refinery in São Paulo state in Brazil is presented in the ‘Análisis energético, exergético y económico de un sistema de cogeneración: caso para una planta azucarera de San Pablo’ by Omar R. Llerena of Universidade de São Paulo (Published in: Ingenius no.19 Jan/Feb 2018 under Creative Commons license CC BY-NC-SA 4.0)

Flows are in kW, and even though this diagram appears to be ‘casero’ made from blocks, triangles and curve shapes, the flow widths seem pretty much to scale.

Acronym ‘CC’ is for the combustion chamber and ‘CR’ stands for a heat recovery boiler (caldera de recuperación).

The article also features a Grassman diagram for the exergy analysis. So, if you are interested, please visit the article here.