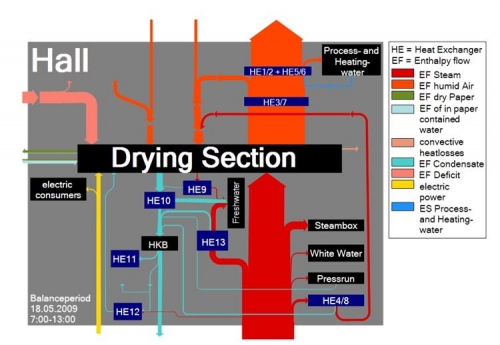

A research project at Technical University Dresden in collaboration with a paper manufacturer aims at detecting and implementing energy saving measures for paper machines.

“Better monitoring of process variables, improvement in the operating point (or range) of the process, installation of heat recovery systems (e.g. at heat exchangers), use of heat pumps and replacement of high energy streams (steam) with waste heat streams. Most of these techniques are standard recipes which are readily available in the market. However they are designed without giving any consideration to the specific aspects of a manufacturing facility and also provide no quantitative evidence of the potential benefits. “

This is why they came up with a mass and energy balance model and are using the following Sankey diagram to visualize where energy could be recovered.

Flows are labeled as

enthalpy flows, showing the changes in thermodynamic (heat) energy at each process step, hence losses. The Sankey diagram is for a balance period of six hours. No absolute figures are given. Several heat exchangers are installed along the wet section of the paper machine. In the drying section, a large part of the energy is lost as steam/humid air.